- 6 October 2022

- Posted by: Canberra Innovation Network

- Categories: Cyber, General News

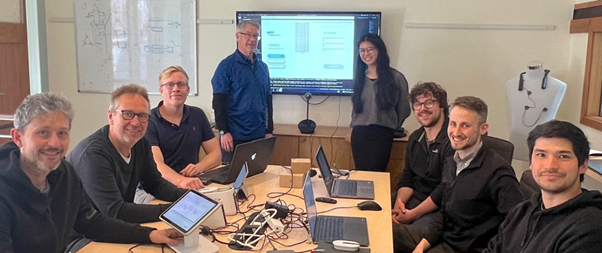

Hub member PPB Technology reached the next milestone in their commercialisation journey this month when they travelled to Melbourne to take delivery of the alpha build of the new generation CYBERTONGUE®.

This is the third version of the original Cybernose/Cybertongue technology. It is markedly smaller than previous versions and uses a radically different operating principle. The new machine is a compact white and silver unit with rounded edges, and is controlled through an ergonomically designed touch-screen panel. Gone are the keyboard and mouse used in earlier versions.

PPB Technology Founder and Managing Director, Dr Stephen Trowell said the new unit looks like an appliance one could easily find on a kitchen bench, but the small size and minimalist design disguises the fact that it is in fact a high performance, laboratory-grade, diagnostic testing device.

Apart from the reduced size, the new machine has a simplified workflow that is much more user-friendly and intuitive.

“We invested a great deal in making the whole system easier to use than any competing technology,” Dr Trowell said.

“We have designed out the need for a user to have fine motor skills and made everything robust and shelf-stable. That required some fundamental under-the-bonnet modifications.”

PPB Technology develops diagnostic tests for food quality and safety, with an initial focus on the shelf life of ultra-high-temperature treated (long life) milk. CYBERTONGUE® is a high-performance diagnostic device for on-site testing, and while its current focus is detecting proteases in milk, in future will be testing for a number of allergens or toxins.

This next generation CYBERTONGUE® was developed by PPB Technology with partners Tricycle Developments for product design, and Xentronics for electronics. Three machines were produced for alpha testing, with one based at each company for each team to work on any system bugs and further refinement. In parallel, production of test reagents is being scaled up with other partners.

After the initial in-house testing, modified units will be shared with customers who have signed up for PPB Technology’s beta testing phase.

“Then we will manufacture our first production batch for commercial launch. We aim to get to that point as soon as possible, and certainly before the end of 2023,” Dr Trowell said.

Find out more about PPB Technology and the work they do here.

Article originally posted by CEAT